Cavanna Packaging Group

The CAVANNA PACKAGING GROUP is a global leader in the design and manufacturing of high speed flow wrapping systems for the bakery, confectionary, prepared foods industries. Their innovative engineering team has conquered some of the most difficult and challenging product handling applications in the packaging automation world. This has resulted in 5000 machine installations worldwide and over 100 patents for technologies developed by them.

The CAVANNA PACKAGING GROUP is a global leader in the design and manufacturing of high speed flow wrapping systems for the bakery, confectionary, prepared foods industries. Their innovative engineering team has conquered some of the most difficult and challenging product handling applications in the packaging automation world. This has resulted in 5000 machine installations worldwide and over 100 patents for technologies developed by them.

With four global manufacturing sites and over 300 employees, Cavanna can provide the quality automation solutions and long term customer support that is essential to success in this important area of sophisticated packaging automation.

One of the primary goals at Cavanna is to develop solutions that address the growing requirement for TCO (Total Cost of Ownership) objectives in the modern food manufacturing environment. These solutions can include robotics or conventional product collation technologies. The innovation extends to the use of new composite materials in the manufacturing process and simulation software to evaluate the potential performance for the most complex applications in the food manufacturing industry.

With a proven track record for reliable performance, their sanitary designs and ultrasonic sealing technology make Cavanna the affordable technology choice for medium and high speed flow wrapping equipment.

Zero4 Wash Down

- Feeding with low linear speed (m/')

- Easy to clean

- New wrapper technology

- Ergonomic structure

- Reduction of space

- Reduction of parts/components

- User-friendly

Zero5 Box Motion

- Hermetic and tight sealing

- Highest speed/performances on market

- Suitable for gas flushing

- Available to accept longitudinal ultrasonic sealing

- Designed for tight application & pharma

- Improvement of productivity

- Improvement of long lasting parts

- Improvement of cleaning ability

- Improvement of accessibility

Twin Slim with G41F

- Biscuit piles independently created

- High space reduction

- Compact & innovative technology

- Improvement of accessibility

- Fully auto system + compact boxing

- Designed for top market level

- New technology & design

- Increased efficiency

- High reduction of manpower

- High level of ergonomics

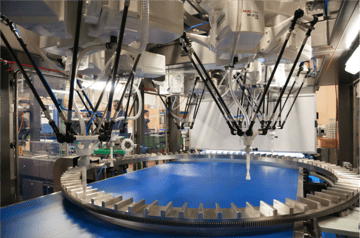

Ring with Zero5

- Product: biscuits enrobed with chocolate

- Way of arrival: randomly

- Dimensions: Ø 56 mm x H 6 mm

- Loader: 6 vision pickers, each handling 60 bpm with Ring device to create biscuit piles

- Wrapping machine: Zero5 with transferring unit

- Final pack: 1 pile of 3 pieces

- Speed: 120 ppm

- Electronic = Allen Bradley

- Robotic vision system electronic = Fanuc

- Checkweigher OCS on wrapper exit