Industry Leading X-Ray

Eagle Pl is a Mettler Toledo company focused in industrial food processing applications. Machine design is centered on MTBF (up-time), leading technology and client serviceability.

Your Canadian operation needs local parts and a strong service team. Since 2009, Plan Automation has strived to build the most comprehensive support network to respond to clients when needed.

Eagle PI Xray represents the most comprehensive array of X-Ray inspection technologies servicing all food processing industries, from analysing your bulk incoming food components to finished shipping case inspection.

Eagle PI Xray represents the most comprehensive array of X-Ray inspection technologies servicing all food processing industries, from analysing your bulk incoming food components to finished shipping case inspection.

We offer solutions for:

+ Single Beam Density Inspection ( for F,NF, SS, Glass, Stone, and Dense Contaminants)

++ Dual Beam MDX Material Discrimination (all above, including plastics/rubbers, bone)

+++ Dual Beam PXT (incredibly enhanced inspection for best contaminate detection)

![]()

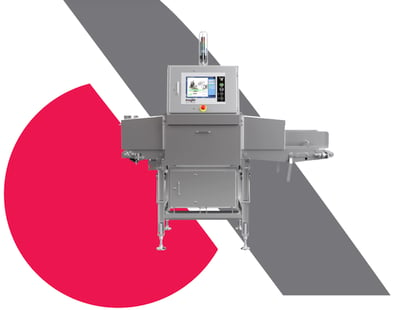

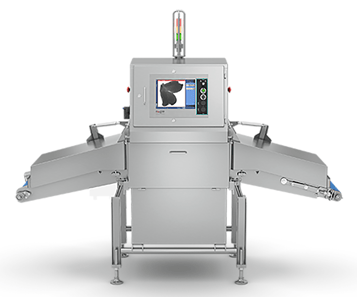

Pack 240 PRO

Designed for x-ray inspection of high-speed flow-wrap lines, blister packs and small packaged products as well as quality checks.

CONTACT US

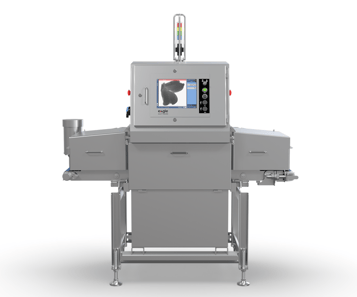

Pack 320 PRO

Designed for x-ray inspection of high-speed flow-wrap lines and small to mid-sized packaged products.

CONTACT US

Pack 430 PRO

Designed for x-ray inspection of mid-sized packaged products and multilane applications in the Food, Pet Food, Pharmaceutical and Personal Care industries.

CONTACT US

Pack 550 PRO

A quality assurance system designed for mid-sized meat, poultry, seafood and dairy products. Built for harsh washdown and multilane applications.

CONTACT US

Pack 720 PRO

Designed for x-ray inspection of large packaged products in boxes or cases and multilane applications in the meat, poultry, seafood and other food industries.

CONTACT US

Pack 1000 PRO

Designed for x-ray inspection of large boxes or cases of multiple, individually-wrapped products in the food, pet food, pharmaceutical and personal care industries.

CONTACT US

Tall PRO XSDV

A multi-functional systems that provides 100% inspection for contaminants in rigid containers such as cans, bottles, etc.

CONTACT US

Bulk 415 PRO

Maximizes contaminant removal while cutting product waste and reducing downtime to boost line efficiency for dry bulk product applications such as nuts, grains, granola, sugar, cereals, coffee and other high-volume bulk products.

CONTACT US

Bulk 540 PRO

Designed to address the unique handling and inspection requirements posed by bulk flowing food products such as fruits, vegetables, pet food, seafood, granola and other cereals.

CONTACT US

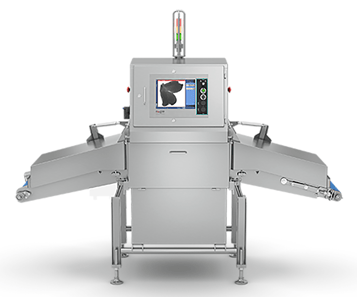

RMI 540

Hygienically constructed to sanitary design for superior bone and contaminant detection in the meat, poultry and seafood industries, where daily sanitation and hygiene requirements are stringent.

CONTACT US

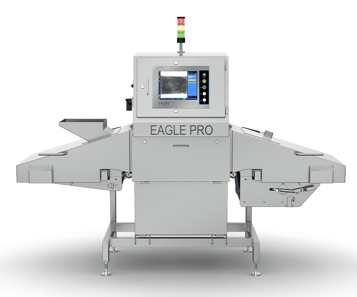

RMI 400

Delivers superior bone and contaminant detection. It is hygienically constructed and built to sanitary design for the meat, poultry and seafood industries.

CONTACT US

RMI3/C

Designed specifically for product inspection of closed cartons or open crates of raw beef, pork, chicken, lamb or similar products.

CONTACT US

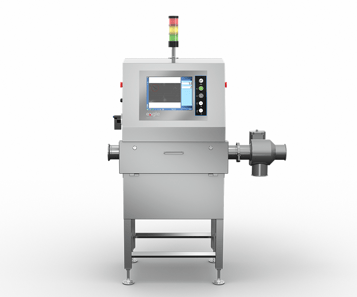

Pipeline

Promotes systematic product flow and delivers optimal detection of contaminants by using active product tracking, while reducing the amount of product rejected.

CONTACT US