Chicken Bone Detection Made Easy

Poultry X-ray Inspection Systems

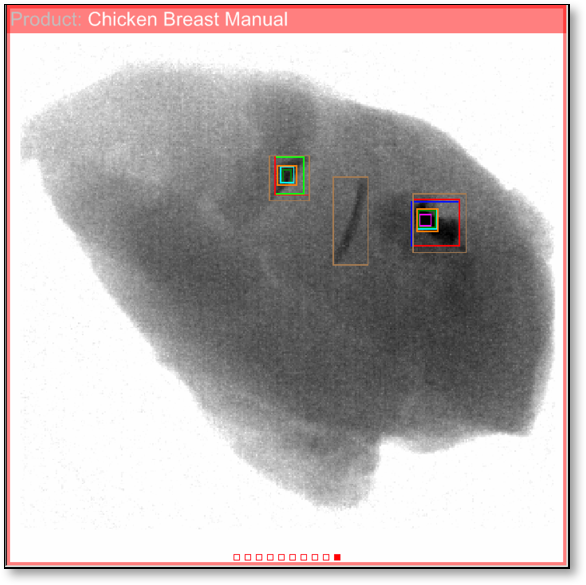

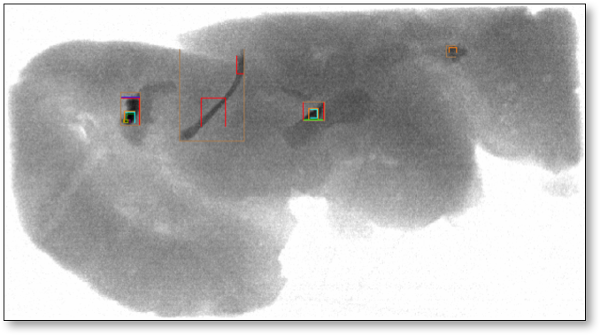

The 400 RMI Poultry X-ray Inspection System

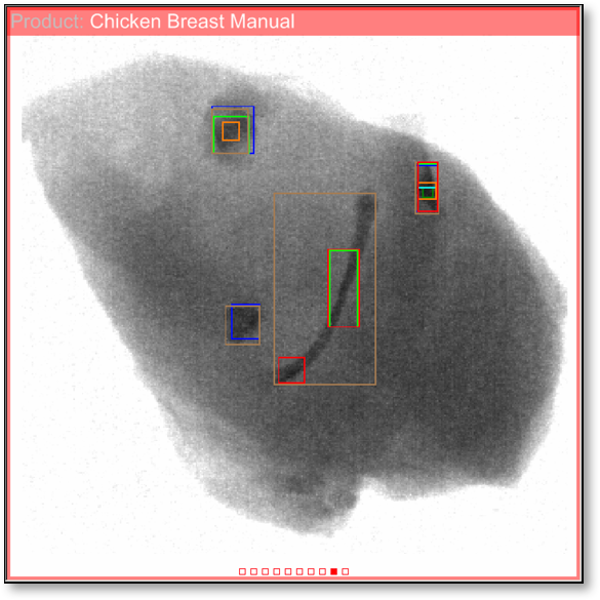

Our new 400 RMI Poultry X-ray Inspection System not only provides enhanced bone inspection (young and older bones), but is also offered at a dramatically reduced cost (VS its predecessor). The system can also be equipped with our new purposed build de-boning in-feed section and re-circulating reject re-work conveyors allowing for higher throughput line efficiency.

Best Available Inspection Capabilities

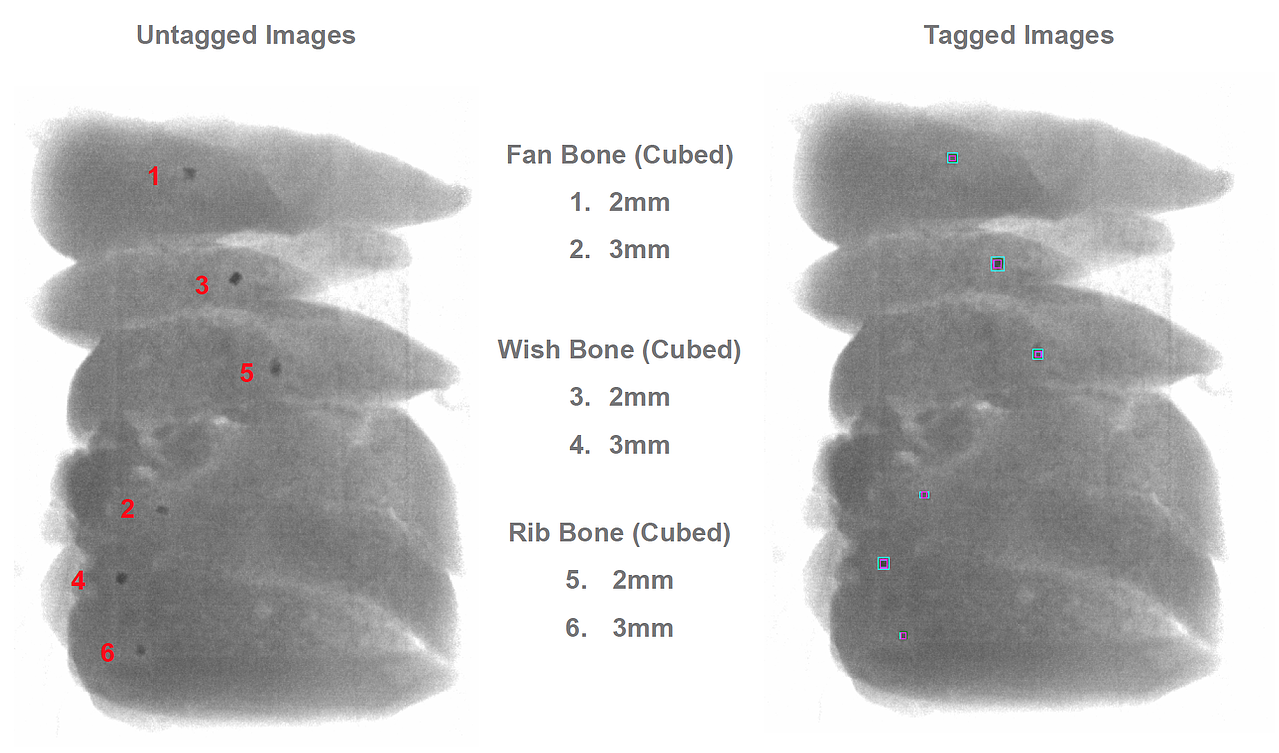

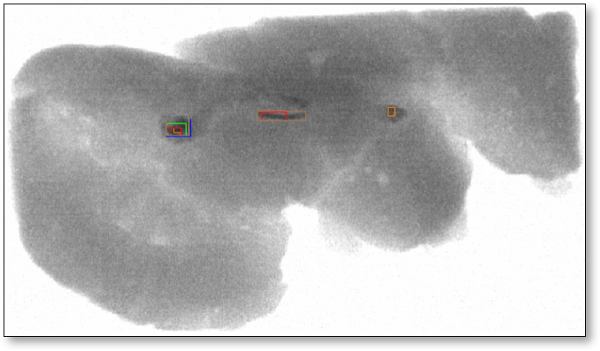

- Detection of bones in young and mature birds

- Bone detection down to 2.0mm - 3.0mm

- Metal detection down to 0.6mm - 1.0mm for Fe, Non-Fe and SS

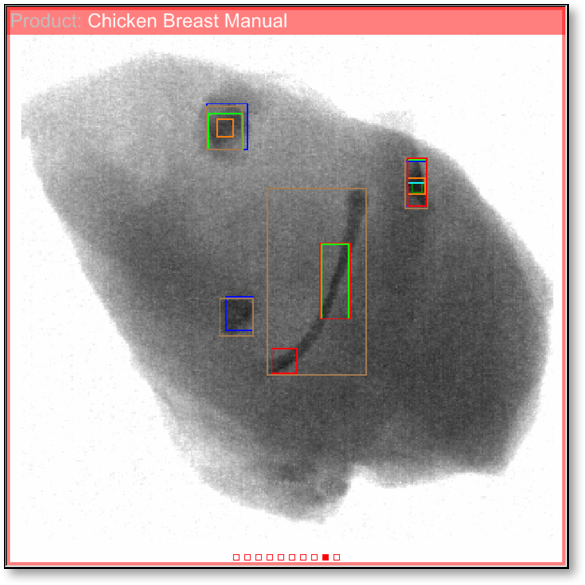

- Other contaminants detection: Glass, stones, high density plastic and rubbers, etc.

Click here to read more from Canadian Packaging Magazine (PDF)

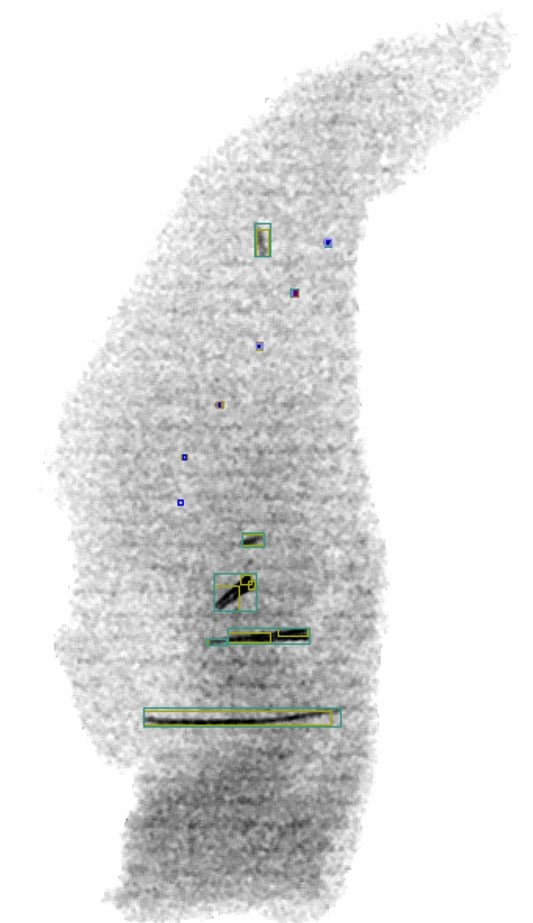

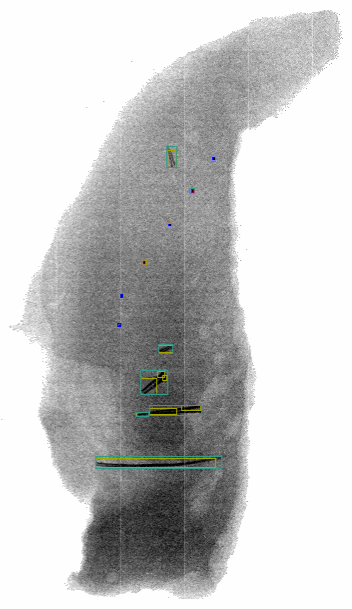

The 400HCP Poultry Enhance X-ray Inspection System

The 400HCP Poultry Enhance X-ray Inspection System

Eagle PI is proud to introduce the new 400HCP Poultry Enhance X-ray Inspection system.

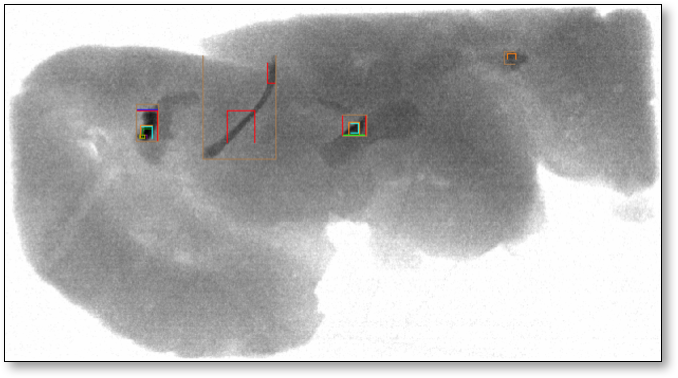

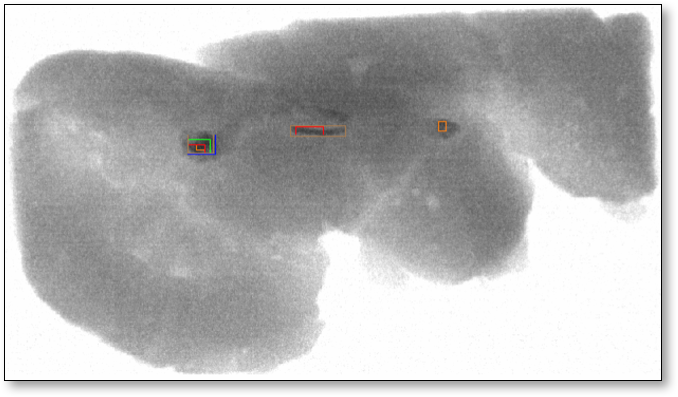

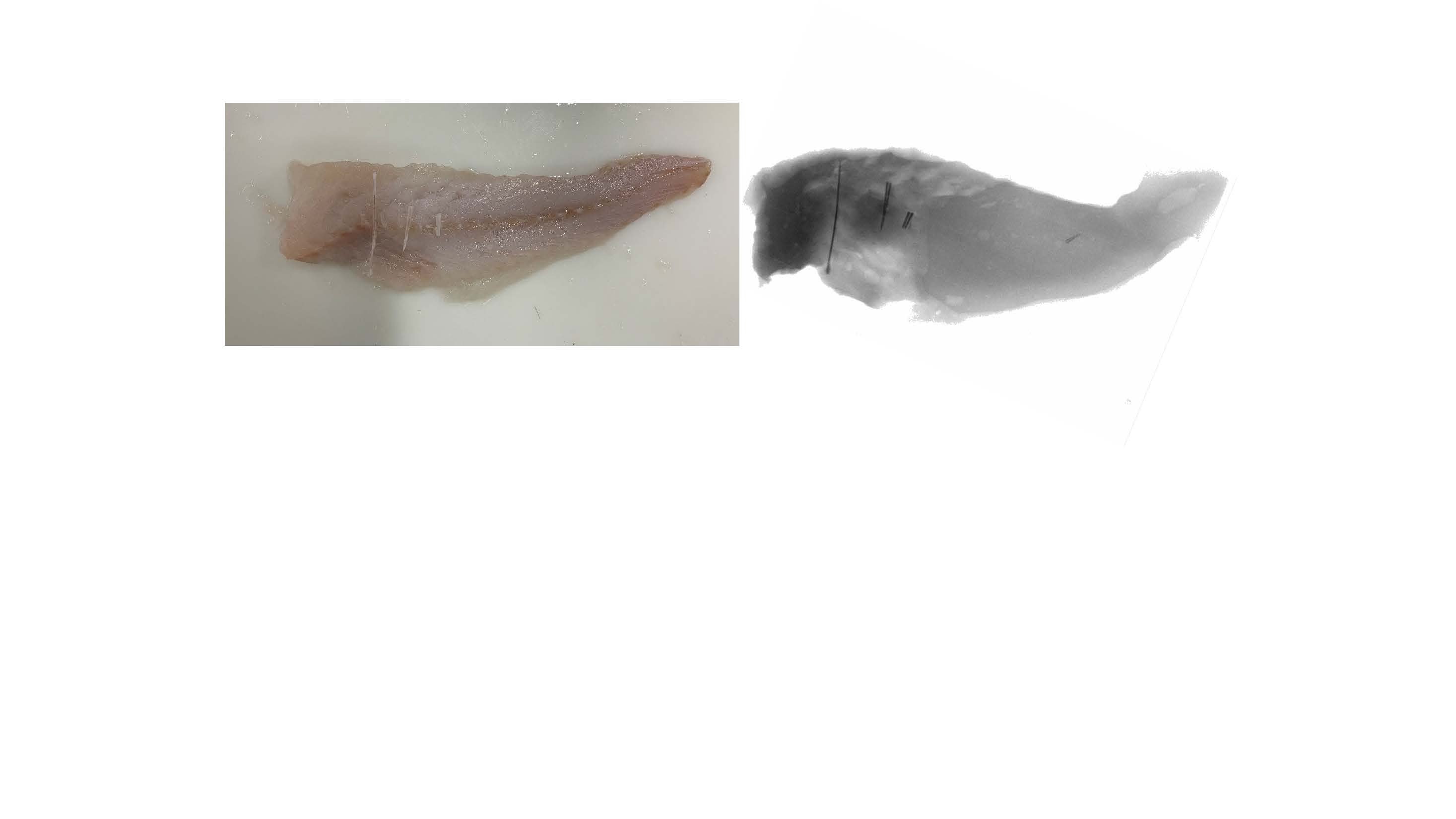

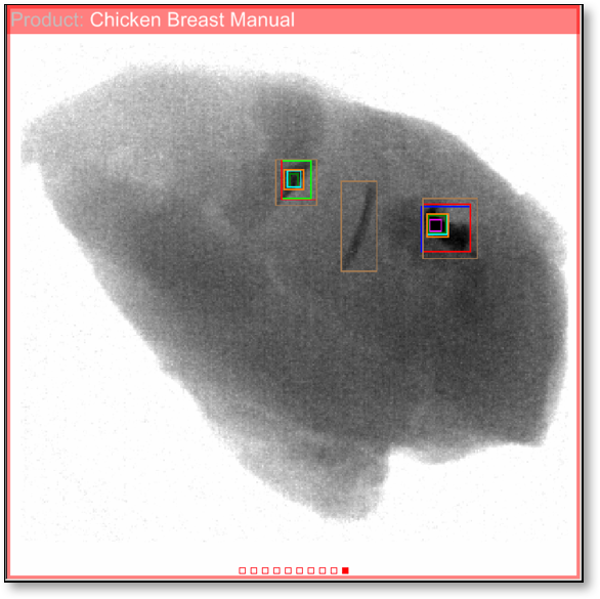

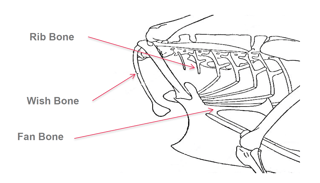

The 400HCP was engineered to meet the stringent inspection demands of the poultry industry. The unique design allows for enhanced poultry bone inspection of both young and mature birds for (wishbone, rib bone, fan bone etc.) in all types of bonesless products such as fillet, trim, tender, nugget, thigh, etc.

Eagle PI designed their system to allow for easy integration to any deboning process and can also be equipped with a multitude of purposed-build modules such as a de-boning in-feed section, reject mechanism, re-circulating re-work light stations, etc. This allows for higher throughput, better line efficiency and lower labor cost.

- Detection of bones in young and mature birds

- Bone detection down to 2.0mm - 3.0mm

- Metal detection down to 0.6mm - 1.0mm for Fe, Non-Fe and SS

- Other contaminants detection: Glass, stones, high density plastic and rubbers, etc.

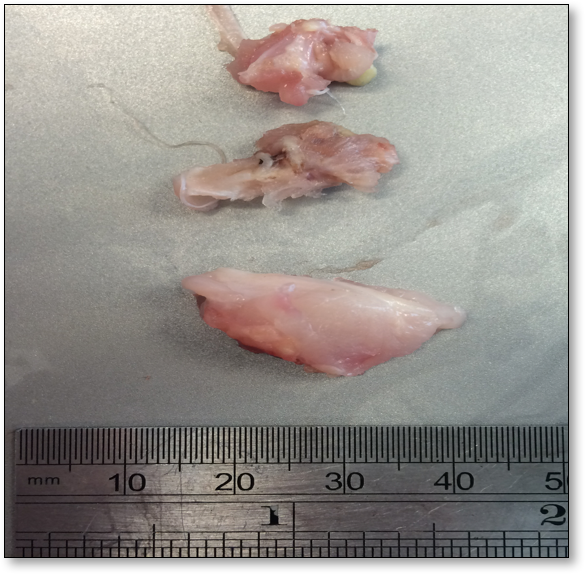

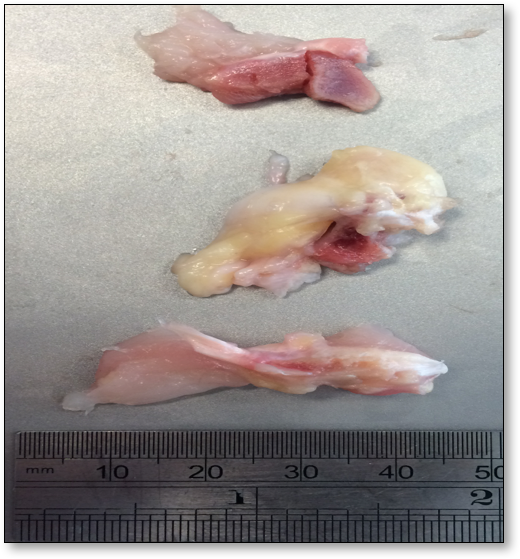

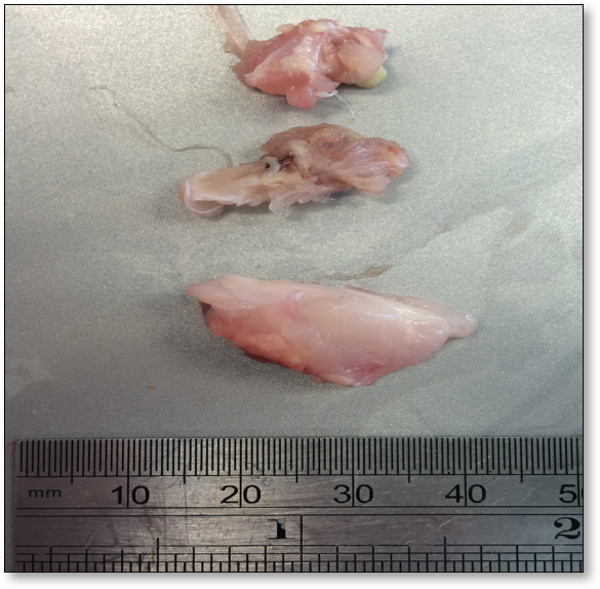

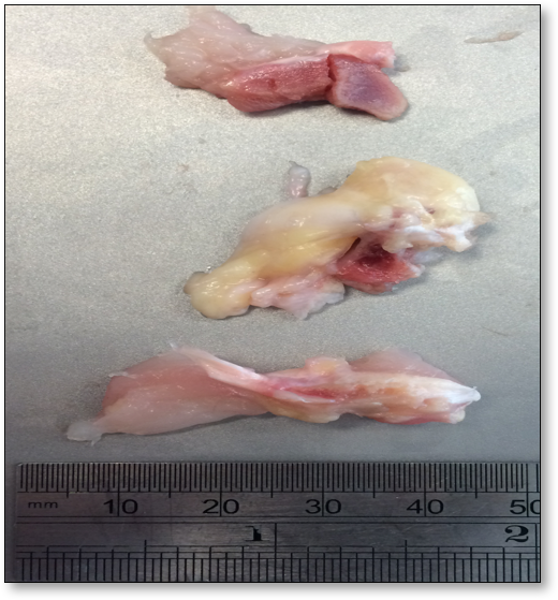

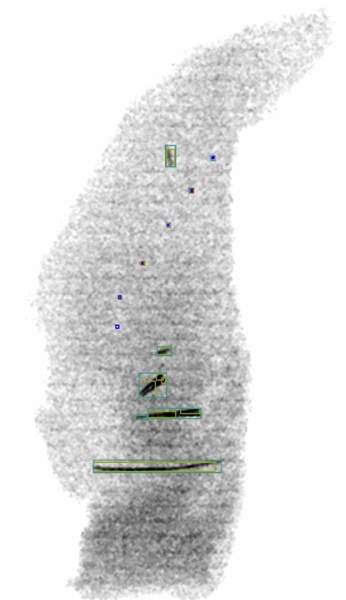

Actual Detected Chicken & Fish Bones

Contact our X-ray Product Specialist directly at:

Mat Bédard

VP, Food Safety and Product Inspection Specialist

Cell: 416-720-7875

Email: mat@planautomation.com