Meat producers have a dire need for accurate fat analysis in their meat products. The problem is that traditional testing solutions such as core sampling can easily suffer from sample bias.

Meat producers have a dire need for accurate fat analysis in their meat products. The problem is that traditional testing solutions such as core sampling can easily suffer from sample bias.

For years, meat producers had to make due with small samples of their meat because the core sampling process was a destructive one. Taking enough samples to get a relatively accurate assessment of the chemical lean of an entire production run of beef would be prohibitively wasteful of materials.

So, meat producers would get by with core sample tests of a few ounces of meat per pound produced. It was a slow, wasteful process.

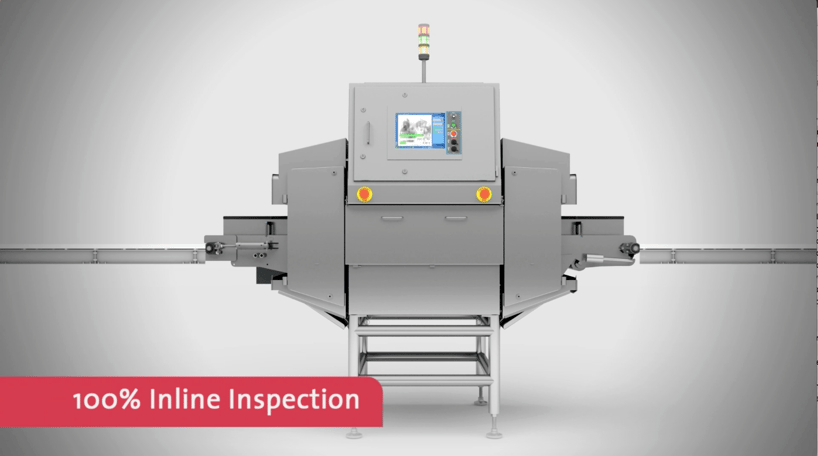

But, there’s a better way to handle chemical lean and contaminant inspection now: inline x-ray fat analysis for meat products.

Why Inline Fat Analysis (CL) Inspection Works

The traditional x-ray product inspection technology was always good at analyzing the density of materials. The traditional grayscale images provided by older x-ray inspection systems have long been used by doctors to study bones.

In more recent years, airport security systems began utilizing dual-energy x-ray systems that could use two different wavelengths of x-rays to study the chemical composition of packages passing through airports. In time, this enhanced technology found its way into the food industry as dual-energy x-ray absorptiometry, or DEXA.

By studying how the meat being passed through the inspection machine absorbs the two different wavelengths of x-rays, the ratio of lean meat to fat content (chemical lean) can be accurately established for every last ounce of meat—without having to destroy any.

DEXA X-ray systems can also provide moisture and protein calculation simultaneously.

The benefits of inline inspection over core sampling include:

- A DEXA X-ray machine can analyze the fat content of meat in mere seconds. Traditional core sampling requires a prolonged test that can take hours.

- With core sampling, you’re only testing a small fraction of a percent of the meat for fat content, so uneven distributions of fat can easily skew results. With DEXA in-line X-ray testing, every ounce of meat is checked, so you have incredibly accurate chemical lean values to work with.

- Non Destructiveness. With core sampling, the samples being tested are destroyed. X-Ray inspection with DEXA technology is harmless to products. It is also very fast which allows for 100% inspection of all meat.

- Simultaneous Contaminant Detection. While a DEXA inspection machine is checking for fat content, it can also provide inspection and reject of numerous contaminants such as: Bones, metal, plastic, glass, stones, etc..

These benefits make for a more productive, accurate production line that reduces lean meat giveaways, contamination recalls, and fat claims significantly.

Integrating an inline meat inspection machine from industry leaders like Eagle PI is easier than you might think! Find out more today!