In the Lanaudiére-Laurentides region of Central Quebec is the Boulangerie St-Donat bakery. This bakery makes roughly 12,000 pies and 3,000 cakes every day Monday through Friday, which are then distributed to grocery stores major chain retailers throughout Canada.

Plan Automation Technology Blog

How X-Ray Inspection Machine Improved St-Donat’s Quality Control

Just How Detectable are Detectable Components?

Detectable components are great tools for reducing your contamination risk in your food production process.

Topics: Metal Detection, Metal Detection Technology, detectable components

How to Ensure Your Product Inspection Reduces Risk of Metal Fragment Contamination

X-ray Inspection and its Quality Assurance Benefits to TCS Foods

United Kingdom-based soup, sauce and

marinade producer, TCS Foods Ltd., has

earned substantial acclaim for its high quality products and commitment to innovations in the food industry. Recipient of countless awards for excellence and quality, TCS Foods Ltd. acknowledges that superb quality food products are the joint result of both the products themselves and the safety of their preparation.

Topics: Metal Detection, X-Ray Inspection, X Ray Inspection for Food, Food Safety and Quality Inspection, X Ray Inspection Technology, Food Product Inspection, Metal Detection Technology, X Ray Inspection of Meat

6 Metal Detector Requirements for GFSI Audits

Preparing for a safety and performance audit requires preparation, thorough documentation and testing on behalf of manufacturers. In compliance with the Global Food Safety Initiative’s (GFSI) new production standards, it is important that manufacturers know and anticipate machine and system requirements prior to auditing, as this can save precious company time and resources, and limit instances of nonconformance with the audit review.

Topics: Metal Detection, Product Inspection, Fortress Technology, Metal Detection Technology, Metal Detectors, GFSI Audits

3 Types of Metal Detection Applications for GFSI Audits

Modern industrial metal detectors have been described as some of the lesser successful machines in auditing tests and examinations, with up to 75% of audits reportedly encountering some type of non-conformance; however, manufacturers can keep their companies out of this statistic by incorporating proper operator training and accurate record keeping. Effective and standardized testing procedures, and the knowledge of how the three metal detection applications function with regard these procedures, can greatly ease the stresses of the auditing process.

Topics: Metal Detection, Fortress Technology, Metal Detection Technology, Metal Detectors, GFSI Audits

Metal Detection Applications for Your Production Line

Metal detection technology, commonly used in the safety and quality inspections of many products, has found a home in the food and production industry. Due to the technology’s accuracy in finding tramp metal many manufacturers have embraced metal detection in their business. For this efficient and developing technology, the list of its applications in production lines grows with every day.

Topics: Metal Detection, Product Inspection, Fortress Technology, Metal Detection Technology, Metal Detectors

Types of Metal Detectors for the Food Manufacturing Industry

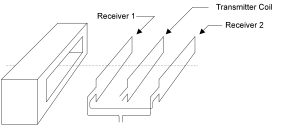

Metal detection technology, one of today’s premier mechanics for safety and quality inspection in the food industry, comes in many different models and types, allowing for seamless integration into any manufacturing production line or system.

Topics: Food Safety and Quality Inspection, Food Product Inspection, Metal Detection Technology, Metal Detectors

The Role of Metal Detectors in the Food Industry

Metal detection technology has recently emerged as an attractive alternative to conventional X-ray inspection methods, being a much less expensive system than X-ray systems while keeping much the same performance in many applications.

Topics: Product Inspection, Metal Detection Technology, Metal Detectors

The Benefits of Metal Detection Technology

The use of metal detection technologies brings the strong potential to lower inspection costs versus X ray while providing much of the same safety and quality assurance benefits. The technology behind and process of metal detection is an elementary system, providing an accessible means for companies to protect the integrity of their brand and company image.