As part of our dedication to continually provide you with the highest levels of service and industry solutions, we are proud to announce that effective August 1, 2025, METTLER TOLEDO has acquired the X-ray and Reclaim related assets of Plan Automation.

Plan Automation Technology Blog

Mat Bedard

Recent Posts

In The News: Plan Automation sees growing demand for X-ray machines for food producers

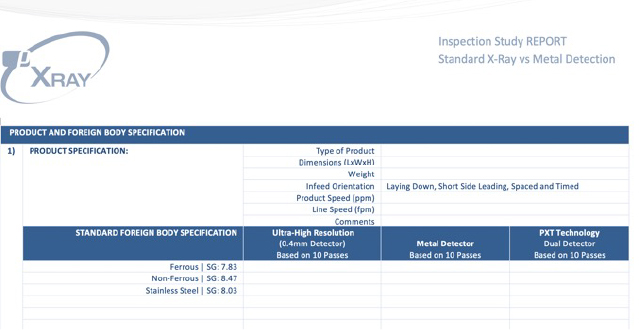

Costco Technology Comparison Inspection Study: Product Testing

X-ray 101: How it works, and how it can improve food safety and increase product quality

Food manufacturers across the globe have been relying on x-ray technology since the early 1990s to protect consumers, reduce the risk of product recalls and safeguard their brands. But what exactly is x-ray inspection and how does it work?

Topics: X-Ray Inspection, X Ray Inspection for Food, Product Inspection, Eagle Pi, emergency x ray systems, X-Ray Solutions

8 Benefits of Using an Automatic Stretch Wrapping Machine

Packaging is the final step of your production line, but the first thing that your customers see after your products are delivered. Efficiency and consistency are the two most important elements of any successful packaging. Good stretch wraps will protect your pallets from dust, damage and other forms of tapering. Although wrapping pallets isn’t complicated, hand stretch wrapping causes inconsistencies. Companies are now finding it easier to invest in stretch wrapping machines that can comply with their unique daily operations.

Topics: Stretch Wrapping, stretch film, Stretch Wrap, stretch film wrapping

What Contaminants Will an X-Ray Inspection Machine Miss?

X-ray product inspection machines have evolved greatly over the years. Modern x-ray machines can detect a wide range of contaminants based on their density or chemical makeup. Additionally, x-ray inspection machines can check package weight, seals and fill level to make sure the package is ready for distribution.

Topics: X-Ray Inspection, Dual Energy X-Ray Absorptiometry (DEXA) Technologi, MDX

Odds are that if you work in the food industry, you’ve heard of x-ray product inspection technology before. This technology has been used to help increase food safety and quality since the early 90s.

Topics: X-Ray Inspection, Dual Energy X-Ray Absorptiometry (DEXA) Technologi, X Ray Inspection for Food, X Ray Inspection Technology, MDX

Avoid Over & Underfilling with a Product Inspection System

There are billions of different packages that are filled every day around the world. A package can mean a jar, bottle, box, tube, a can or any other container filled with a product. According to the law, all prepackaged goods should display the volume or net weight and the number of pieces. In the modern world, the value of a product is much more than just its functions and sealable elements including image and safety.

Some simple products incorporate these elements because they can influence their compliance with the regulatory requirements. You should conduct product inspection checks thoroughly, including checking whether packages contain what they are labeled in legal quantities.

Topics: Product Quality, X Ray Inspection for Food, Food Product Inspection

Should You Use Single Energy X-Ray Technology for Food Inspection?

Food inspection has become an essential element in food production. Contamination of food with any impurities may cause serious repercussions to your business with safety programs such as Hazard Analysis and Critical Control Point (HACCP). This is because of the product liability law which states that every food producer is liable for any contamination of the products they make if a consumer gets harmed. Regular rubbers and plastics can also pass through inspection radars—which can cost you dearly.

Topics: X Ray Inspection for Food, X Ray Inspection Technology

What to Look for in On-Site Emergency X-Ray Inspection Services

Whether it’s a bone that manages to remain wedged in a piece of meat, a loose screw that eventually falls off a machine, or bits of plastics that find their way into your batch, any contaminants in your finished product will be a major blow to your brand. The enactment of the FSMA (Food Safety Modernization Act) has led to many industries emphasizing food contamination prevention. Therefore, you should meet the mandatory preventative controls to comply with the FSMA, and X-ray inspection equipment is key to ensure food safety.