Innovations in automated x-ray inspection technology have allowed the manufacturers of countless industries to limit unnecessary expenditures on materials and labor throughout their production lines, primarily by simplifying

safety inspection processes.

For those skeptical of x-ray inspection at face value, a review of the safety systems and quality control compliance in their own facilities can prove useful, and give real-world incentive for making the switch to x-ray. How much do you spend monthly, or annually, on product recalls or poor, batch-style filtering?

1.) Optimized Systems for Efficient Product Approval

If one product in a large group contains imperfections or contaminants, should that

entire group be compromised? X-ray inspection [MB1] generates significant savings over time by optimizing product detection and automating reject lines with pinpoint accuracy.

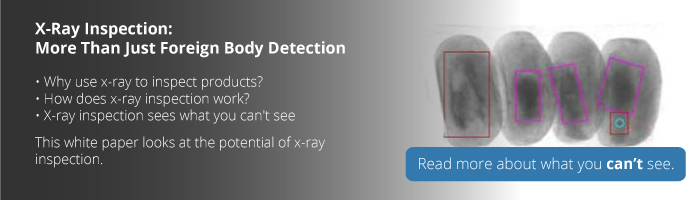

Using advanced x-ray beams and detailed 3D imaging capabilities, modern x-ray inspection technologies can detect virtually any irregularities or contaminants in a product, down to even the smallest occurrences.

As these systems can be seamlessly integrated at any point in a production line, be it during raw product processing, pre-distribution preparation or packaging, product rejection is pushed to optimum efficiency. What this means for your business is product rejection of only products that need rejection and recycling; one faulty product in a batch will not cost you the entire batch to recycle and repurpose.

With innovative x-ray inspection tools installed, manufacturers can find and correct product irregularities at any point in the production process, in areas they may have not even thought possible with inspection technologies, such as fill levels and product air pockets. Among these factors, x-ray systems can also detect:

- Metallic or non-metallic contaminants

- Packaging irregularities, such as missing cap, incorrect fill level, broken seals and missing inserts

- Improper product positioning

- Incorrect product weight

- Incorrect product count

- Deformed products, such as those featuring flavor lumps

2.) Immediate Savings in Labor

While material and product recycling savings will only become evident after the time it takes to repurpose those goods, the benefits to your facility’s workforce and labor efficiency will be evident almost immediately.

Unlike waiting for new numbers on your inspection process (the material savings you can gain through x-ray inspection technology), you can see instant savings in valuable work hours; What this means is that you’ll wind up spending workforce hours more efficiently, and save money on processes that don’t necessarily require human supervision, such as automated x-ray inspection.

3.) Better Allocation of Work and Production Budget

With these saved labor hours, you can much more effectively allocate workers to tasks and areas in your facility that are more demanding of their attention. X-ray automation does not need continuous supervision, management or maintenance to effectively detect and resolve product quality issues. Instead of assigning workers to these menial, tedious tasks, you can rather focus on improving other areas of your production operation.

In these cases, better-managed work hours translate into more appropriate spending behaviors, and lessened budgetary strain. Once a manufacturer has installed innovative x-ray inspection systems in their facility, at whatever point in the production process they deem most suitable, the potential for productivity boosts are virtually guaranteed.

Almost everything about x-ray machines and their integration with existing systems is determinable by the user; when installed at optimal points in a production line, delivering the greatest savings to labor, materials and costs, x-ray inspection tools are the end-all, be-all solution for automated product safety. Using the time saved by x-ray inspection systems, users can tackle other areas of improvement in their facility, and boost their revenue and savings in broader, business-wide ways.

4.) Brand Protection and Consumer Image

Of course, the biggest way x-ray inspection technologies, such as the innovative systems built by Eagle PI, generate real savings for production operations concerns how well they help preserve brand identity and consumer opinions.

With highly accurate x-ray technologies equipped, you will never again have to worry about embarrassing product recalls, or whether or not contaminants may irreversibly tarnish your brand image in the eyes of the public. Your brand identity is controlled by various factors, such as your products themselves, imagery and company engagement with consumers, but also product safety and quality control.

Compliance with food product quality standards, such as Global Food Safety Initiative (GFSI) and HACCP standards, is made simple with x-ray inspection technologies. This can save your company significantly, by eliminating the risk of financially devastating product recalls and brand dissatisfaction.

To learn more about how modern innovations to x-ray inspection technology can benefit your business in both quality assurance and financially supportive ways, contact us today.