In many of our posts about x-ray product inspection, we’ve frequently discussed the benefits of x-ray inspection to the food industry. However, the food industry isn’t the only one that can benefit from the use of x-ray inspection technology.

In many of our posts about x-ray product inspection, we’ve frequently discussed the benefits of x-ray inspection to the food industry. However, the food industry isn’t the only one that can benefit from the use of x-ray inspection technology.

Another major industry that frequently uses x-ray inspection to great benefit is the pharmaceutical industry.

How do pharmaceutical companies benefit from the use x-ray inspection? Many of the benefits for the pharmaceutical industry are similar to ones enjoyed by the food industry, and include:

Reduced Risk of Product Recalls

Foreign bodies in medication packages can be just as severe of a problem for pharmaceutical companies as it is for processed food companies.

Foreign bodies in medication packages can be just as severe of a problem for pharmaceutical companies as it is for processed food companies.

When metal shavings or other contaminants are left in pharmaceutical products, they pose a health hazard to the customers who are taking the medication in order to improve their health. Such injuries can result in expensive lawsuits and enormously negative press, not to mention extensive product recalls to pull potentially contaminated products from the market.

In addition to checking for foreign contaminants, x-ray inspection machines can check for missing products and faulty packaging.

For example, say that a pharmaceutical company makes asthma inhalers. These are emergency-response medication delivery systems, so the need to work right the first time. An x-ray inspection machine can check for the presence of critical components, such as the inhaler’s locking level, and make sure that such components are in place, and reject inhalers that are missing crucial parts.

This helps ensure that only fully functional inhalers leave the production facility so that users can breathe easy when they need their inhaler. Sending out incomplete or damaged medication delivery systems can lead to severe risk of patient injury or, in extreme cases, death, so checking for product completeness is a must.

Easy Verification of Missing Products in Sealed Packaging

With healthcare costs being what they are, customers hate feeling that they’ve been shortchanged. Using manual inspection methods, it is difficult, if not impossible, to verify that the right number of syringes are in a closed and sealed package.

However, with x-ray product inspection technology, it is easy to get a look inside of a sealed package and get an exact count of the number of syringes in the package to make sure that you giving customers exactly what they paid for rather than shortchanging or oversupplying them.

X-ray machines can also check product packages by weight. This way, containers of common over-the-counter medications can be checked by their total weight to see if there is enough medication within to meet the expected amount for that product package.

While not a severe safety issue compared to contaminated products, checking for missing products helps to keep customer satisfaction up and complaints down.

Savings on Inspection Labor

Manual inspections take time to complete, forcing you to either create a production bottleneck or add extra labor until there is enough to handle the inspection demand.

X-ray machines can rapidly inspect products, saving time and labor on your product inspection process. In fact, with the ability to integrate with automated product rejection systems, some x-ray inspection equipment can operate almost independent of human operators for hours at a time.

Ability to Prove That Product Safety Standards Were Followed

From time to time, documentation of procedures is every bit as important as the procedures themselves.

Some x-ray inspection machines can generate reports for product rejections, complete with an image of the rejected product that can be used for reporting compliance with product safety standards later.

Why is this important?

To summarize it in one word: traceability.

Many product safety standards require that all products and events be traceable back to their origins and at each step of the production process. Without the appropriate records, this is impossible to do. With x-ray inspection records of rejections, on the other hand, you have a record that your company was meeting product inspection requirements and working to keep the public safe.

When products with defects do make it out of the production facility, these same x-ray records can make it easier to facilitate recalls and minimize the scope of the recall.

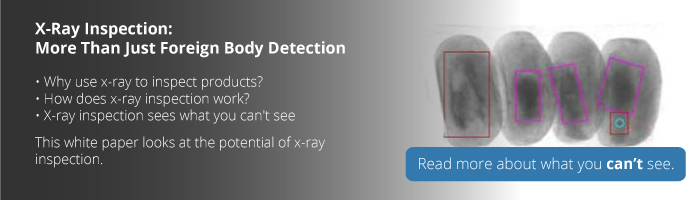

There are many more ways for the pharmaceutical industry to benefit from the use of x-ray inspection. To learn more about using x-ray machines to enhance product safety check out the free whitepaper at the link below: