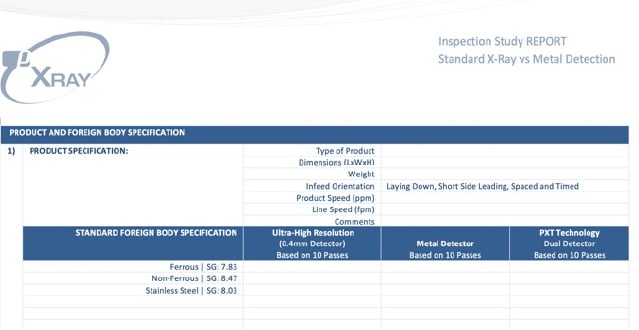

Plan Xray Technical Food Safety Centre provides 3rd party comparative reporting for standard xray vs metal detection inspection capabilities.

Food processors interested in understanding inspection performance difference between Xray and metal detection, provide their package product for comparative analysis performed at Plan Xray by a certified Xray / metal detection technician.

A comparative inspection capability report details findings based on standard CPP contaminates samples (F,NF,SS).

Inspection Study Parameters:

Individual bar and carton testing:

- Multiple different SKUs and multiple different sizes per SKUs

- Tested using 3 different technologies:

- Metal Detection

- Xray – Single Energy

- Xray – Dual Energy

- Foreign Bodies that can be tested

- Ferrous

- Non-Ferrous

- Stainless steel

- Stainless Steel Wire

- Aluminium

- Glass: Low mineral

- Glass: High mineral

- Glass: Quartz

- Ceramic (stone analogue): Steatite

- Ceramic (stone analogue): Zirconia

- Ceramic (stone analogue): Porcelain

- Ceramic (stone analogue): Alumina Oxide

- PTFE (Teflon)

- Xray Detectable Acetal

- Phantom Bones: Poultry Bones

- Customer supplied foreign body

- Test sampling size for each foreign body: 10 – 100, customer dependent

- Foreign body placement on the product: Top and bottom

- Check-weighing testing for each SKU

- Testing speed and throughput: As per the client needs

- Report turnaround time: 2-4 weeks, depending on our workload

- Process is fully customizable