Food safety is an enormous concern for modern businesses. The reputation of your brand and the ability to make sales depends on how safe your products are.

Food safety is an enormous concern for modern businesses. The reputation of your brand and the ability to make sales depends on how safe your products are.

A single food safety incident can cause untold harm to your operations in the form of investigations, lawsuits, and lost sales as consumer trust wanes. The importance of food safety and quality inspection is well-established.

The real question is, “how can you maximize food safety to minimize risk of an incident?”

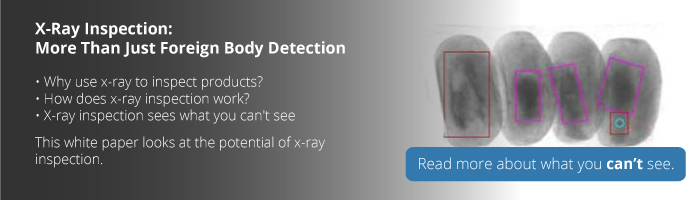

This is where modern x-ray product inspection technology can help.

Detecting a Variety of Food Contamination Risks

X-ray technology has evolved considerably from the basic density imaging technology that it once was. Rather than just making a grayscale snapshot of a food product, modern x-ray systems frequently use a dual-energy setup that can actually assess the chemical composition of food packages and their contents.

This includes both material discrimination x-ray (MDX) and dual-energy x-ray absorptiometry (DEXA) technologies.

By analyzing chemical composition in addition to the grayscale image of food products and packages, MDX and DEXA systems can detect a wider variety of contaminants than traditional x-ray systems or metal detectors. Examples of contaminants modern x-ray systems can detect include:

- Dense rubber

- Metal shavings

- Bone chips (even from chicken)

- Dense plastics

- Glass

- Stones

- Etc.

This broad range of contaminant detection helps x-ray inspection machines greatly lower the risk of product contamination, but there’s more to product safety than this.

X-Ray Inspection and Package Checks

One of the biggest challenges in inspecting products for contaminants is that many inspection technologies struggle with checking the contents of a sealed package—especially with metalized packages.

Normally, this means putting your product inspection checkpoint just before the packaging phase of the production process. However, with x-ray inspection, you are able to check the contents of a sealed package.

MDX and standard X-ray inspection machines can spot non-metallic contaminants in sealed glass or plastic containers with ease, and are even able to detect contaminants in metalized packages or in packages with metal componets (i.e. metal caps).

Beyond simply checking for foreign bodies, modern x-ray systems can also perform numerous other quality checks in sealed packages, including:

- Fill level inspection

- Weight checks

- Missing caps/components

- Broken seals

- Chemical lean in meat products

- Incorrect product dimensions/count

- Etc.

By detecting these quality defects, x-ray inspection machines can prevent food safety risks beyond just foreign bodies in products.

Placing X-Ray Inspection Machines for Greatest Effect

To get the biggest impact out of your product inspection equipment, it’s often necessary to carefully consider where you should put it on your production line. Performing a comprehensive hazard analysis critical control point (HACCP) check can be very helpful here.

Placing x-ray machines at the earlier phases of your production process, such as ingredient inflow, can help you spot contaminants early to prevent them from making it into your mixers, vats, and other production equipment. However, this leaves you open to hazards such as metal shavings from production equipment making it into the final ingredient mix.

Placing x-ray machines near the end of the production process allows for a strong final check of product packages prior to distribution. However, this may end up in more ingredients being wasted if contamination occurs.

If you only can have one x-ray inspection machine, placing it later in your production process is strongly recommended, as it will help you better avoid a food safety incident. On the other hand, if you can get multiple x-ray inspection machines, you can place them at both the start and finish of your process—which greatly increases your chances of detecting contaminated products before they make it to distribution.

Having multiple inspection machines or technologies for inspecting your different ingredient inflows increases your ability to trace contaminants back to their source, which can aid in your efforts to improve product safety in the future as well.

Get started with x-ray product inspection to maximize your food safety and protect your brand today!