Dual Energy X-Ray Absorptiometry (DEXA) technology is one of the best product inspection technologies for the meat production industry. This is a revolutionary technology that every raw meat producer should have on their production line.

Plan Automation Technology Blog

Mat Bedard

Recent Posts

Top 3 Reasons to Use DEXA Technology for Meat Inspection

Food Safety Issues: Is Your 3rd-Party Certification FSMA Accredited?

Food safety is a major concern for businesses in all corners of the food industry. According to estimates by the Center for Disease Control, “each year roughly 1 in 6 Americans (or 48 million people) get sick, 128,000 are hospitalized, and 3,000 die of foodborne diseases.”

X-Ray Inspection and Product Safety in Food Industries

For any packaged food manufacturer, product safety is of the utmost concern. When products are unsafe, they can create a public relations nightmare that can be difficult for any company to recover from.

Topics: X-Ray Inspection

Evaluating the Benefits of Automated X-Ray Inspection for Your Business

At this point, x-ray product inspection is a well-established technology with numerous benefits for processed food manufacturers throughout Canada and the U.S.A.

Topics: X-Ray Inspection

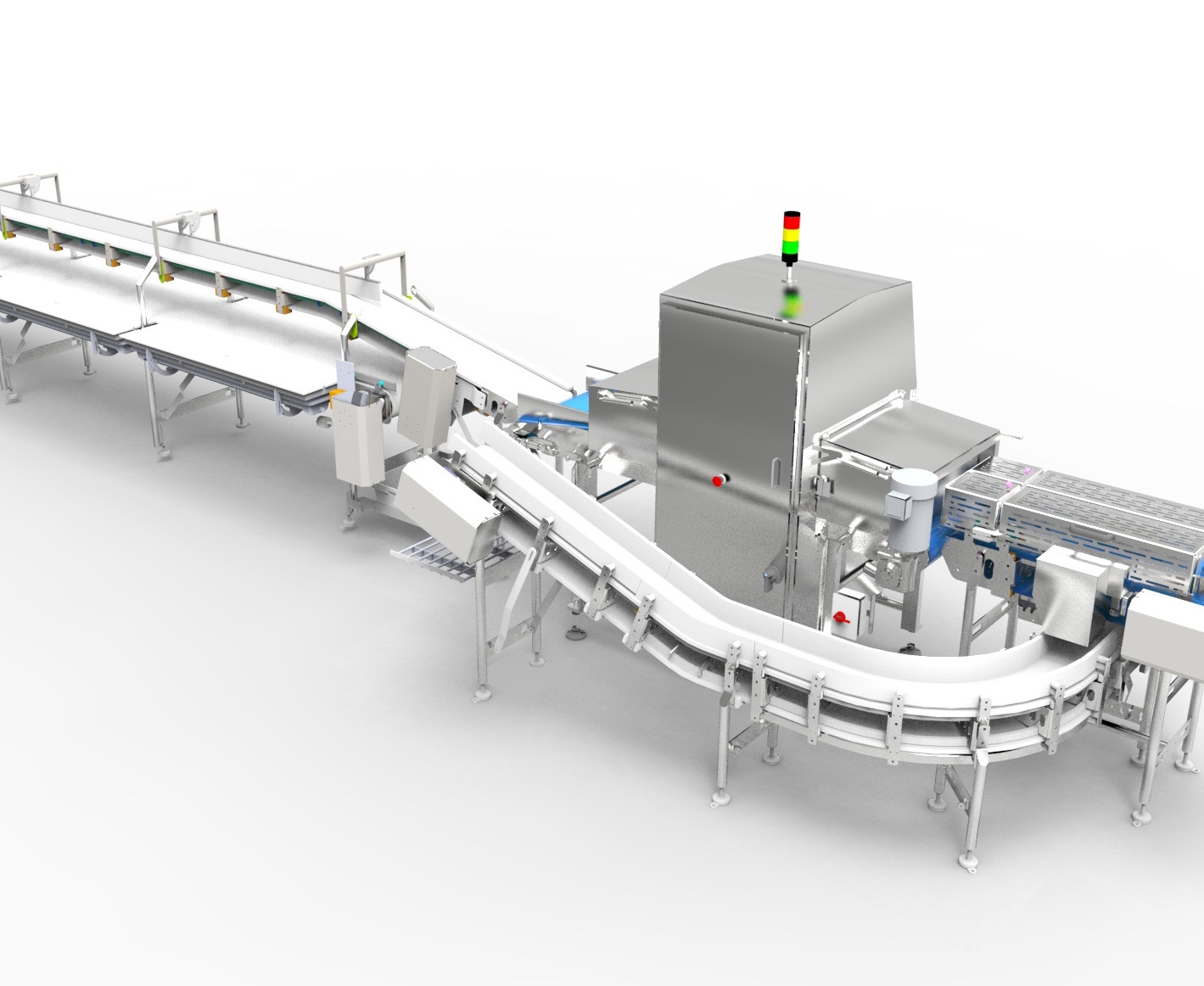

X-Ray Product Inspection Machines and Sanitary Design Principles

Bacteriological contamination is an enormous concern for companies that process raw meat. Infections such as listeria and e. coli are an enormous threat to the safety of food products and the customers who consume them.

Examples of foodborne bacteriological outbreaks continue to make the news each year, such as the e. coli outbreak in late 2015 that affected consumers in California, Washington, Utah, Montana, Colorado, Virginia, and Missouri.

Topics: Product Inspection

How Do I Procure Processing Equipment for My Company’s Applications?

For consistent production and the highest quality products, successfully integrating the right processing equipment is a must for food and beverage industries. In these sectors, processing design quality can determine branding success, and set businesses apart from others in highly competitive markets.

Topics: processing equipment

DEXA, or Dual Energy X-ray Absorptiometry, is a game-changing product inspection technology for the meat production industry.

This technology expands on the capabilities of traditional x-ray product inspection technology by using two separate x-ray energy wavelengths, one high-energy wave and one low-energy wave.

Topics: X Ray Inspection of Meat

Prevent a Poultry Emergency with X-Ray Inspection for Chicken

Any manufacturer handling raw meat products faces numerous challenges every day. Ensuring that all tools are sanitary, that workers are following sanitation guidelines, and that meat is free of contaminants is a full-time job.

Topics: Food Inspection

Customizable Component Parts for Your Industry’s Unique Needs

Accidental equipment and product contamination aren’t uncommon within food, beverage and pharmaceutical production industries. There are always risks present, whether through employee mistakes or even your own line equipment, which can put your goods and brand in danger.

Topics: detectable components

In the food industry, it’s becoming more and more important to make sure that products not only get made fast enough to keep up with demand, but to ensure that these products are free of defects that could harm or upset consumers.

Topics: X-Ray Inspection