Adjusting products to the correct fill levels manually can lead to operator error, increased downtime, and wastage. However, today there exists modern quality inspection equipment that can monitor the correct fill levels and adjust the filler heads to ensure that you are compliant—without the product and time wastage which often happens through product giveaway or reworking. Performing these adjustments and measurements during full production can provide a significant edge in a competitive market and increased productivity for your business

Adjusting products to the correct fill levels manually can lead to operator error, increased downtime, and wastage. However, today there exists modern quality inspection equipment that can monitor the correct fill levels and adjust the filler heads to ensure that you are compliant—without the product and time wastage which often happens through product giveaway or reworking. Performing these adjustments and measurements during full production can provide a significant edge in a competitive market and increased productivity for your business

Incorrect fill-levels can place your business at a risk of litigation and product recalls. Therefore, performing an inspection of all your products can help avoid such risks of underweight products being distributed to your clients.

Why Should You Perform a Fill Level Inspection?

Other than ensuring product safety, most systems can perform other quality checks without interfering with production speed. A fill level inspection system can perform a gross mass measurement to minimize product giveaway, and can also be connected to your filling system upstream to adjust content automatically, provide feedback control, and to eliminate future product over or under fill.

Other reasons why you should perform a fill level inspection include:

Average Content Legislation

Most countries have one or more legislations that are based on the averaging system which is often derived from contents that are indicated on the label or container. Therefore, over and underfill inspection can help in controlling the average.

Minimum Content Legislation

Legislation can dictate the contents that should be indicated on the label or container and the minimum to be in the container. In such a case, an underfill inspection can help control & prevent underfilling.

Yield

Overfilling is a waste of products which can be a source of huge profit loss for your business. Most manufacturers judge their performance by the yield, and an overfill inspection can assist in yield management.

Customs

If you produce high duty products such as wines and spirits, Customs and Excise will control overfilling because duty calculation is based upon contents that are indicated on the label or container. An overfill inspection will help you avoid Customs and Excise fines and penalties.

Headspace

Headspace is also referred to as vacuity (gap between nominal fill level and the brim of the container) and is important in allowing expansion of the container, especially for products in corked containers and products that have high CO2 levels. In such a case, an overfill inspection will help protect vacuity.

Merchandise Integrity

Headspace is important in all products that are heat treated (cooked or pasteurized) because excessive fill levels can inhibit the product from moving and this would cause the product to be partially cooked. And, at extreme overfilling, this can deform the container or even cause it to burst during the heat treatment. An overfill inspection will help you maintain the required headspace.

Aesthetics

Your product has a brand identity, and its appearance should be important to you when it comes to sales. Keep in mind that even after packaging and following all legal guidelines, your product may still look different when the fill levels vary. As a brand owner, ensure you use an under and overfill equipment to help you control the consistency of your product to end consumers.

Why You Should Use Fill Level Inspection Systems

The main objective of fill level inspection systems is to make sure that any glass bottles, metal cans, or other composite containers are well filled to the correct height. These systems also ensure that the beverage containers are accurate in the labeled contents and also verify the correct headspace for heat treatment. With such a system, you can be able to calculate the average fill level to inspect the minimum levels, check for over or underfills, and also evaluate your filler performance.

Most of the packaging operations in the Pharmaceutical and food industries require a form of fill inspection. Although the applications may vary depending on the product you produce, effective fill inspection equipment should:

- Ensure that you conform to the label and local content regulations.

- Help you reduce or even eliminate product recalls due to incorrect fill levels.

- Reduce giveaway of products through overfilling.

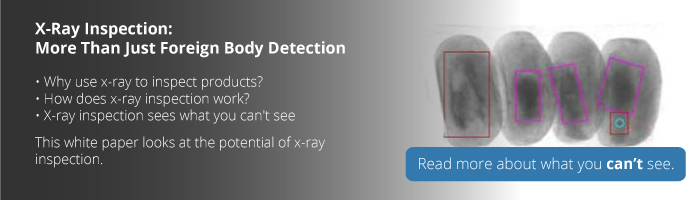

Why You Should use an X-ray Fill Level Inspection System

X-ray systems are now being widely used in many industries due to their several benefits. Other than helping you maintain correct fill levels, it will enable you to detect contaminants such as metal fragments, plastic and rubber compounds, and they have other quality control checks that you can carry out simultaneously.

To identify the best correct fill levels x-ray equipment that can benefit your business, ensure that you contact us today.