Following the terrorist attacks of September 11, 2001, the U.S. Food and Drug Administration’s (FDA) increased security emphasis on tamper-resistant seals on food packaging. To provide quality assurance of their products and packaging seals, nationwide dressing and sauce manufacturer Ken’s Foods looked toward powerful X-ray inspection technology.

Plan Automation Technology Blog

Case Study Highlight: X-Ray Inspection and Ken’s Foods

Topics: X-Ray Inspection, X Ray Inspection for Food, X Ray Inspection Technology, Eagle Pi

Types of Metal Detectors for the Food Manufacturing Industry

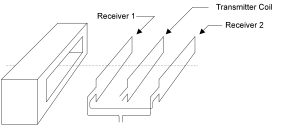

Metal detection technology, one of today’s premier mechanics for safety and quality inspection in the food industry, comes in many different models and types, allowing for seamless integration into any manufacturing production line or system.

Topics: Food Safety and Quality Inspection, Food Product Inspection, Metal Detection Technology, Metal Detectors

The Importance of Food Safety and Quality Inspection

Never has more stress and emphasis been placed on food safety and quality assurance than today, where recalls and consumer dissatisfaction can completely and irreparably ruin brand images. Due to this incredible focus on food and consumer safety, effective inspection technologies and techniques have become paramount to a manufacturer and brand’s success.

Topics: Metal Detection, X-Ray Inspection, Food Safety and Quality Inspection, Food Inspection

The Role of Metal Detectors in the Food Industry

Metal detection technology has recently emerged as an attractive alternative to conventional X-ray inspection methods, being a much less expensive system than X-ray systems while keeping much the same performance in many applications.

Topics: Product Inspection, Metal Detection Technology, Metal Detectors

The Benefits of Metal Detection Technology

The use of metal detection technologies brings the strong potential to lower inspection costs versus X ray while providing much of the same safety and quality assurance benefits. The technology behind and process of metal detection is an elementary system, providing an accessible means for companies to protect the integrity of their brand and company image.

PLAN Automation Wins Eagle PI’s Best Global Partner Award for 2013

Industry-leading automation experts and distributors, PLAN Automation, recently took home Eagle PI’s “Best Global Partner” award for 2013, an award granted to Eagle’s best in sales. PLAN Automation is one of Canada’s most effective and successful automated technology providers, and this award solidifies their status as a leading automation resource.

Topics: Plan Automation Awards, Product Inspection, Eagle Pi

In the modern food and beverage industry, quality products and safety are key components in building successful brands. There are a variety of new and developing technologies today that all but eliminate the need for human inspection of products and goods. Because assuring this quality is pivotal in the successful distribution of some goods, like meats, incredibly accurate technologies, like X-ray machines, may be employed to get more accurate results.

Topics: X-Ray Inspection, Product Inspection, X Ray Inspection of Meat

Utilizing X-ray Inspection Technology on Your Production Line

The presence of X-ray inspection technologies along food service and production lines has never been greater or more prevalent than it is today. With consumers’ growing sentiment for quality products, food production companies large and small are seeking better ways to assure the safety and ensured quality of their products.

Topics: X-Ray Inspection, X Ray Inspection for Food, Product Inspection

The Benefits of X-ray Product Inspection Technology

The use of X-ray technologies in the safety and quality inspections of food products has irrefutable beneficial effects for companies, products and their customers. Simplifying the inspection process with incredibly accurate and quick results, the process of X-ray inspection captures both minor product flaws and severe imperfections, defects that can tarnish the integrity and public opinion of your company.

Topics: X-Ray Inspection, Product Inspection

Improve Packaging Automation with 4 Case Packing Options

Modern case packing and end-of-line product preparation have technologically grown and expanded upon the traditional methods of packaging. Automation is the fastest growing and most promising technique for the contemporary packing of materials, with seemingly endless applications and wide possibilities for system integration. The sleek, dynamic machines of today have transformed the process of packing into a seamless art, taking with them the core mechanics of packing and improving on them with today’s technologies.

Topics: Packaging Automation, Case Packing, End of Line Automation