United Kingdom-based soup, sauce and

marinade producer, TCS Foods Ltd., has

earned substantial acclaim for its high quality products and commitment to innovations in the food industry. Recipient of countless awards for excellence and quality, TCS Foods Ltd. acknowledges that superb quality food products are the joint result of both the products themselves and the safety of their preparation.

substantial acclaim for its high quality products and commitment to innovations in the food industry. Recipient of countless awards for excellence and quality, TCS Foods Ltd. acknowledges that superb quality food products are the joint result of both the products themselves and the safety of their preparation.

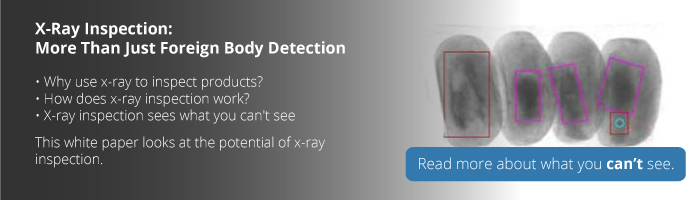

Even with the most organic, healthful food products, poor inspection and production processes can cost a manufacturer everything. To perform their inspection processes at the fullest potential and assure the overall quality of their sauces, TCS Foods Ltd. made the smart choice of bringing innovative x-ray inspection technologies to their production lines.

Unique Challenges Call for Unique Solutions

TCS Foods Ltd., privately owned and responsible for much of the sauce, soup, entrée and dessert production across the United Kingdom, posed unique inspection challenges due to the complexity of their systems and processes.

Unlike traditional production lines, the nature of TCS Foods’ products made it impossible to simply integrate an x-ray inspection machine and leave it to its business; “set and forget” installation was a near impossibility for their facilities. Instead, the company needed to acquire an inspection system that would prove compatible at crucial points in their production… primarily, the product weighing stage.

In TCS Foods Ltd.’s production lines, powerful inspection tools are required immediately after the recipe mixing, pouch filling and sealing application. As product pouches are filled and sealed at a rate of 55 cycles per minute (220ppm), and product temperature can often vary from anywhere between 63˚C and 83˚C, maintaining ideal pouch weight is essential in TCS Foods’ production.

The Need for Change

Traditionally, TCS Foods Ltd. employed metal detection technology and check weighers for their product inspection needs. While these technologies were able to effectively catch metal contaminants and maintain an accurate product weight, they performed at inefficient speeds; lowered speeds that simply did not work with their high-pace, high output production systems. Furthermore, their metal detector was unable to detect non-metallic contaminants such as glass, stones, bones, etc.

Weight verification at TCS Foods’ production speeds was an inaccurate and impractical process, and the need for change was evident… for these reasons, TCS Foods Ltd. began looking into their X-ray inspection options.

When their search for newer, more efficient inspection systems began, TCS Foods Ltd. looked into three main companies with innovative x-ray equipment, and eventually opted for Eagle PI, particularly for the company’s knowledge in check-weighing processes and the weight capabilities of x-ray systems.

Implementing Stronger Solutions

Upon consultation, Eagle PI identified their high-speed

Pack 240 system as the most compatible option for TCS Foods’ production lines. After in-house testing, Eagle reported 1.0 mm detection accuracy and weight detection with accuracy up to 0.29 grams; the most impressive stat of these tests, however, was that the Pack 240 system delivered these results at production speeds of 65 cycles per minute.

compatible option for TCS Foods’ production lines. After in-house testing, Eagle reported 1.0 mm detection accuracy and weight detection with accuracy up to 0.29 grams; the most impressive stat of these tests, however, was that the Pack 240 system delivered these results at production speeds of 65 cycles per minute.

Following a trial period of a single day, TCS Foods Ltd. made their first purchase of an Eagle PI inspection system; the results and performance benefits were that instant. Specially equipped with twin air-blast rejects, TCS Foods Pack 240 systems are designed to meet the specific requirements of U.K. codes of practice.

After just three months with one system installed, TCS Foods Ltd. called for an order of two additional inspection systems. Upon arrival of the new systems, administrators of TCS Foods Ltd. were surprised at how easily the equipment integrated with their existing recording system.

“We never expected to be able to link up the units to our CDC software system,” said TSC Area Manager Shane Barrick, after the systems were integrated in their facilities. “We can actually control the units remotely via the CDC interface, thus allowing us to ensure that the correct product is selected at all times.”

Today, TSC Foods Ltd. has implemented Eagle x-ray inspection technologies throughout their company, making them the standard inspection systems at all levels of their production operations.

Mr. Barrick had the following to say about partnering with Eagle PI, and integrating their innovative solutions in TSC production lines:

“Working with Eagle is great. We get to know the people and they are always there to help out when we need them to. The service and response we get from them is first class. This is more along the lines of what I would expect from a small local company, not a large multinational company.”

To learn more about what highly efficient x-ray inspection systems can bring to your business, or how these technologies can generate both short- and long-term benefits for your production operations, contact us today.