No one in the food industry wants to deal with a product recall for several reasons:

Plan Automation Technology Blog

How to Ensure Your Product Inspection Reduces Risk of Metal Fragment Contamination

How to Lower Your Contamination Risk with Detectable Components

Controlling and limiting contamination risk during manufacturing is a critical step in any production process. Whether your facilities use x-ray inspection solutions or metal detection to assess product quality, there are still inherent risks for contamination along production lines.

Topics: Metal Detection, X-Ray Inspection, Product Inspection, detectable components

What You Can Do to Stop Production Equipment Contamination

In today’s production environments, product safety and the risks of contamination are more ingrained in operations than ever before. No matter what industry your company specializes in (food, beverage, pharmaceutical, etc.), the quality of your products is as decisive for your brand as the actual goods you create.

Topics: Metal Detection, X-Ray Inspection, automation, Product Inspection, detectable components

4 Real Ways X-Ray Inspection Can Save You Money

Innovations in automated x-ray inspection technology have allowed the manufacturers of countless industries to limit unnecessary expenditures on materials and labor throughout their production lines, primarily by simplifying

safety inspection processes.

Topics: Metal Detection, X-Ray Inspection, X Ray Inspection for Food, Food Safety and Quality Inspection, Product Inspection, X Ray Inspection Technology, Food Inspection

6 Metal Detector Requirements for GFSI Audits

Preparing for a safety and performance audit requires preparation, thorough documentation and testing on behalf of manufacturers. In compliance with the Global Food Safety Initiative’s (GFSI) new production standards, it is important that manufacturers know and anticipate machine and system requirements prior to auditing, as this can save precious company time and resources, and limit instances of nonconformance with the audit review.

Topics: Metal Detection, Product Inspection, Fortress Technology, Metal Detection Technology, Metal Detectors, GFSI Audits

Metal Detection Applications for Your Production Line

Metal detection technology, commonly used in the safety and quality inspections of many products, has found a home in the food and production industry. Due to the technology’s accuracy in finding tramp metal many manufacturers have embraced metal detection in their business. For this efficient and developing technology, the list of its applications in production lines grows with every day.

Topics: Metal Detection, Product Inspection, Fortress Technology, Metal Detection Technology, Metal Detectors

The Role of Metal Detectors in the Food Industry

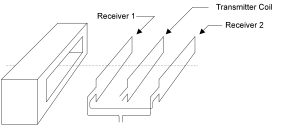

Metal detection technology has recently emerged as an attractive alternative to conventional X-ray inspection methods, being a much less expensive system than X-ray systems while keeping much the same performance in many applications.

Topics: Product Inspection, Metal Detection Technology, Metal Detectors

The Benefits of Metal Detection Technology

The use of metal detection technologies brings the strong potential to lower inspection costs versus X ray while providing much of the same safety and quality assurance benefits. The technology behind and process of metal detection is an elementary system, providing an accessible means for companies to protect the integrity of their brand and company image.

PLAN Automation Wins Eagle PI’s Best Global Partner Award for 2013

Industry-leading automation experts and distributors, PLAN Automation, recently took home Eagle PI’s “Best Global Partner” award for 2013, an award granted to Eagle’s best in sales. PLAN Automation is one of Canada’s most effective and successful automated technology providers, and this award solidifies their status as a leading automation resource.

Topics: Plan Automation Awards, Product Inspection, Eagle Pi

In the modern food and beverage industry, quality products and safety are key components in building successful brands. There are a variety of new and developing technologies today that all but eliminate the need for human inspection of products and goods. Because assuring this quality is pivotal in the successful distribution of some goods, like meats, incredibly accurate technologies, like X-ray machines, may be employed to get more accurate results.

Topics: X-Ray Inspection, Product Inspection, X Ray Inspection of Meat