Odds are that if you work in the food industry, you’ve heard of x-ray product inspection technology before. This technology has been used to help increase food safety and quality since the early 90s.

Odds are that if you work in the food industry, you’ve heard of x-ray product inspection technology before. This technology has been used to help increase food safety and quality since the early 90s.

But, there are many who have questions about x-ray technology, including what it is, how it works, and what it can do for food manufacturers.

To help answer these questions, here’s an x-ray 101 post to cover the basics of x-ray product inspection:

What Are X-Rays?

You might recognize x-rays as a staple tool for doctors’ offices—especially if you or a family member ever been treated for a broken bone.

X-rays are a form of electromagnetic radiation that are invisible to the naked eye. Because x-rays have a very short wavelength, they are able to pass through objects that block electromagnetic waves in the visible light spectrum.

However, denser materials, such as bones, have a tendency to absorb x-rays rather than letting them pass through. This is why when you look at an x-ray “picture,” you see the bones of the body as white areas and the softer tissues around them are a darker gray.

How Do X-Ray Product Inspection Machines Work?

An x-ray inspection machine passes a product or package under one or more x-ray generators. These generators emit a beam of x-ray wavelength energy to a special detector.

An x-ray inspection machine passes a product or package under one or more x-ray generators. These generators emit a beam of x-ray wavelength energy to a special detector.

As the product or package passes between the generator and the detector, some of the x-rays get absorbed. The detector then records the changes in how much of the x-ray beam is reaching it.

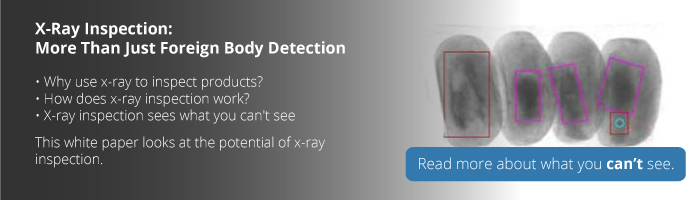

In older, single-generator/emitter x-rays systems, a grayscale image is generated of the product or package. This image is then compared to a previous acceptance standard. If the image deviates from the acceptance standard, the package/product is rejected.

Newer systems use two x-ray generators to emit x-rays on two different wavelengths. This allows the x-ray machine’s computer to analyze the absorption rates of the individual x-ray waves and compare them. By doing so, the x-ray machine can discern the chemical makeup of the product being passed through it. These systems are often known as Dual-Energy X-ray Absorptiometry (DEXA) or Material Discrimination X-ray (MDX) units.

Key Components of an X-Ray Inspection Machine

- An X-Ray Generator. Most modern x-ray machines use a vacuum tube with an electrode pair—one anode and one cathode—with an extreme voltage difference between the two. The positively-charged anode (usually made of tungsten) draws electrons from the cathode. When the electrons collide with the tungsten atoms, photons are generated with high energy levels—enough to be in the x-ray wavelength spectrum.

- A camera designed to record x-ray spectrum wavelengths sits opposite the generator. Once captured, the recorded image is transmitted to a computer for analysis. The images captured are procedurally generated line by line as the product passes through the narrow beam.

- For safety reasons, food x-ray systems have a protective, high-density casing designed to keep any excess x-rays from escaping. The average x-ray machine exposes nearby workers to less than 1 microsievert (1 μSv) of radiation per hour, whereas normal daily living exposes people to 2,400 μSv throughout the year, or 6.57 μSv of radiation a day.

- Most x-ray inspection machines have a built-in computer that is used to govern system actions and to automatically analyze x-ray images. It is this computer that compares the grayscale image to the acceptance standard and rejects products with contaminants.

There are many more components, such as conveyor belts, that may be part of a given x-ray machine, but the above systems are the most vital for an x-ray machine’s operations.

What Can X-Rays Machines Detect?

X-ray inspection machines excel at detecting high-density foreign objects in most products. Things such as stone, dense animal bones, most metals, and glass are often easily detected by x-ray machines.

Lower-density contaminants, such as light metals (like aluminum), wood, low-density plastics, and human hair are usually very difficult to detect.

Detectability of some contaminants may depend on their size and the sensitivity of the specific x-ray machine you use. For example, MDX systems have an easier time detecting small pieces of glass and aluminum than older single-emitter systems.

X-ray systems may also be able to check for other quality issues beyond contaminants depending on their configuration. Common alternative quality checks an x-ray system might perform include:

- seal integrity

- package weight

- fill level

- component inclusion/absence

These extra quality inspection capabilities allow x-ray machines to fulfill a broad range of quality assurance requirements using a single device.

Learn more about x-ray inspection and how it can benefit your production today!