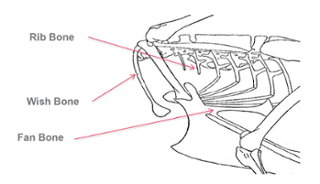

When dealing with poultry, ensuring the complete and safe removal of chicken bones from your products is an enormous challenge. Between the wish bone, the rib bones, and the fan bone, there are many small and fragile skeletal structures in this land fowl that can shatter and get stuck in the meat.

When dealing with poultry, ensuring the complete and safe removal of chicken bones from your products is an enormous challenge. Between the wish bone, the rib bones, and the fan bone, there are many small and fragile skeletal structures in this land fowl that can shatter and get stuck in the meat.

These bones create a health hazard for consumers, one that can damage your company’s reputation. So, ensuring the complete removal of chicken bones from poultry products is of paramount importance to any poultry food company.

But, how can you be sure that there are no chicken bones in your packaged poultry products?

One way to be sure is to use poultry x-ray inspection machines to check your packaged food products.

Finding Organic Compounds in Organic Materials

In the past, detecting chicken bones with an x-ray inspection system would be difficult. Chickens, like most birds, have a hollow, low-density bone structure. Not only does this make chicken bones easy to break into dangerous shards, it rendered them hard to spot in a density-based x-ray image.

However, modern x-ray inspection systems have greatly increased capabilities compared to older models.

For example, the new 400 RMI Poultry X-ray Inspection System from Eagle PI has been optimized to detect bone shards in meat as small as 2 or 3mm in size in both young and mature birds. Using a unique tube / detector configuration allows for organic, low density substances such as bone to be spotted in meat products with ease.

Detecting Other Contaminants

Naturally, bone shards aren’t the only kind of contaminant that you’ll have to handle. So, while the 400 RMI specializes in detecting chicken bone shards, it can spot a variety of other contaminants, including:

- Metal fragments (down to 0.6mm – 1.0mm in size);

- Glass;

- Rubber;

- Stone;

- High-density rubber / plastic,

- Etc.

By detecting a wide variety of potential contaminants, these poultry x-ray inspection machines can help to minimize your risk of contaminated or dangerous products leaving your production facility and making their way to customers.

Protect your customers, protect your brand, and protect your poultry with a poultry food safety initiative-enhancing x-ray food inspection system today!